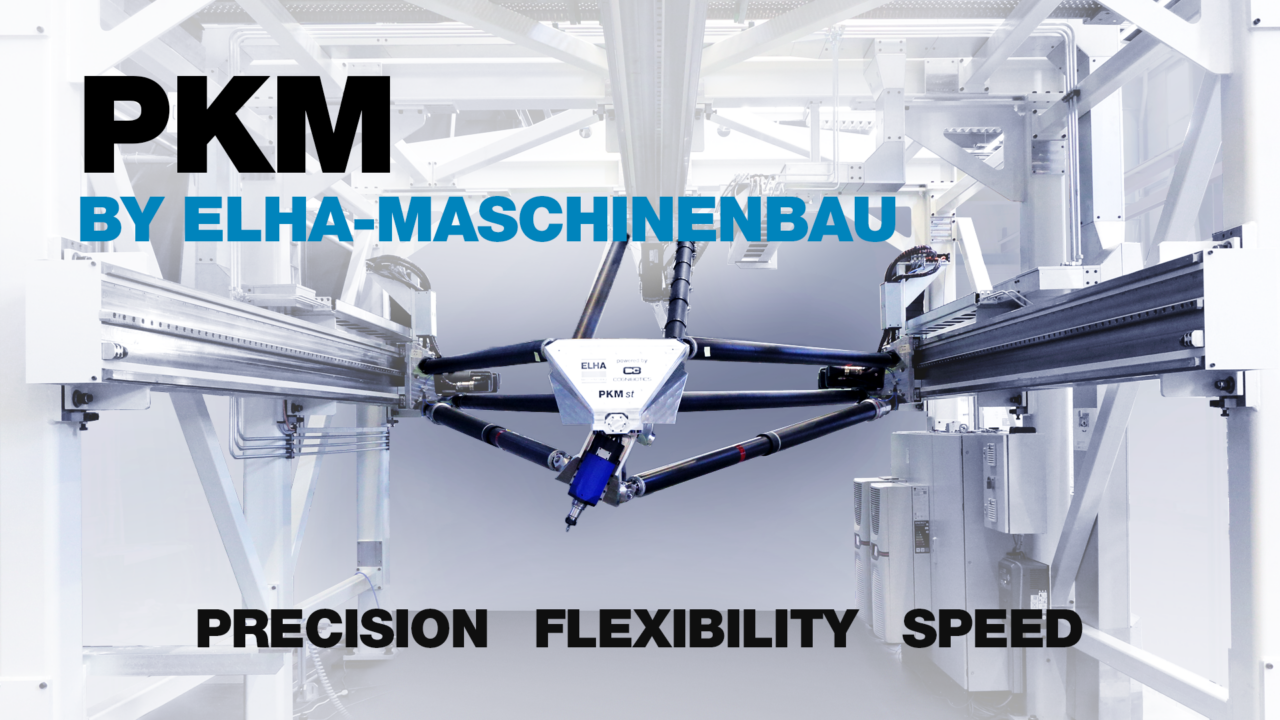

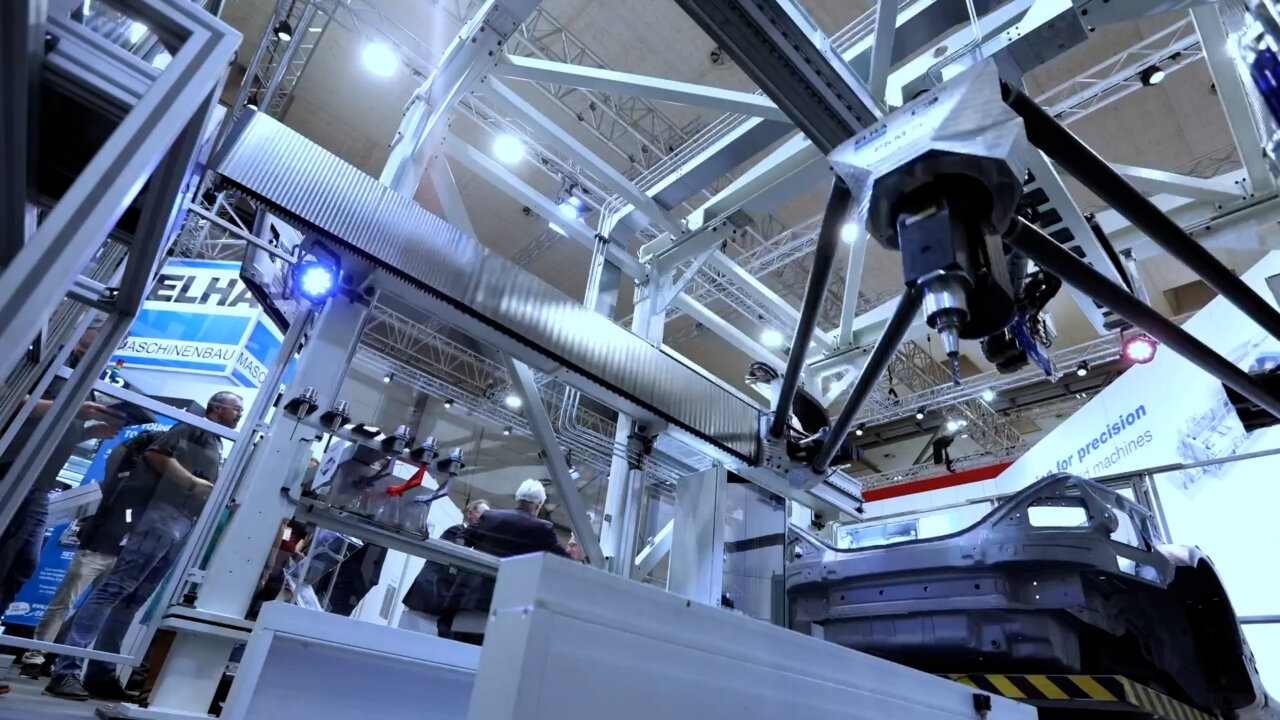

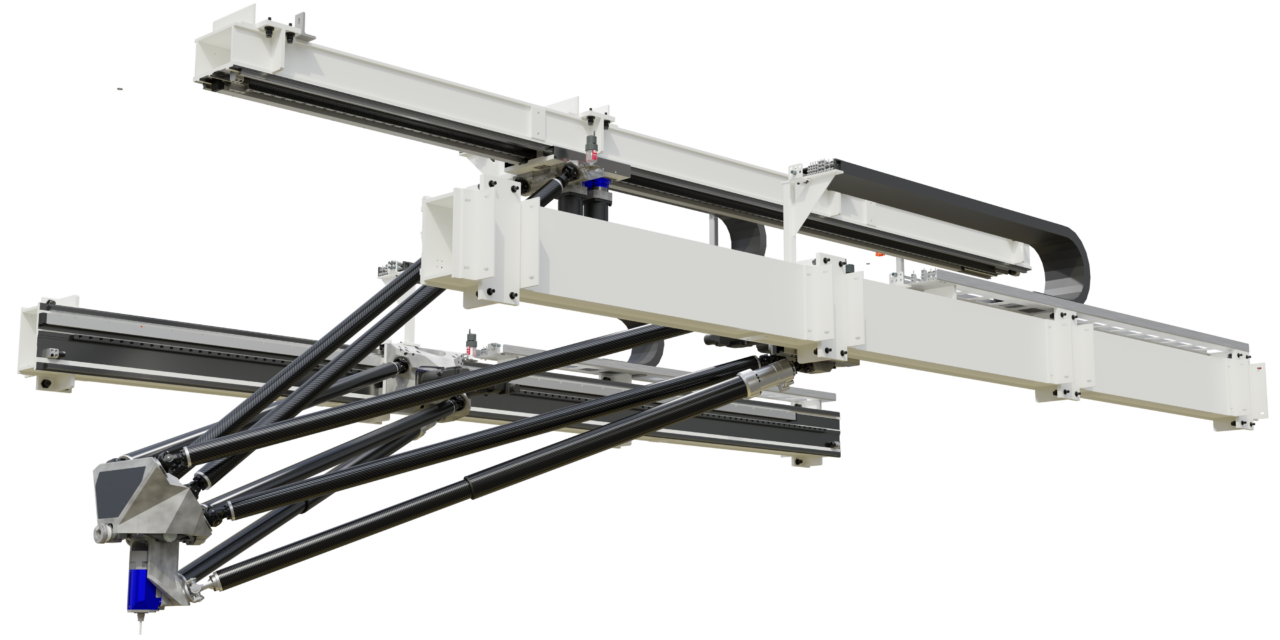

The ELHA PKM is a modular machine that can be equipped with a wide range of end effectors. Compared to serial robots, it offers an increase of 10 to 15 times higher stiffness and accuracy on the end effector.

The innovative mechanical structure allows geometric variations of the base frame, thus adapting the workspace. The PKM distributes loads on the building foundation and offers maximum flexibility during installation, as no additional foundations are required.

High-Speed Cutting

Find out more about metal processing and the options available to you

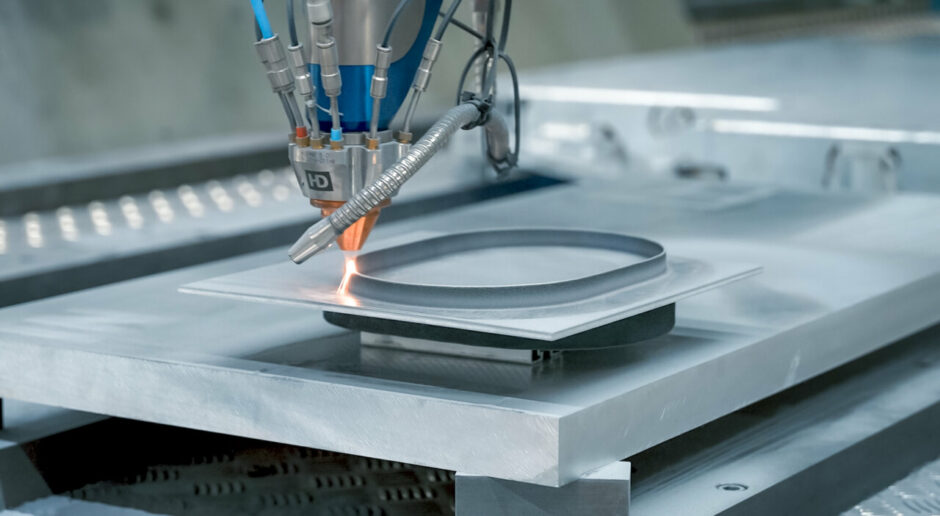

3DMD

Near netshap prints, post-processing and machining of large components with one setup

Vibration Drilling

Vibration drilling in large-scale manufacturing.

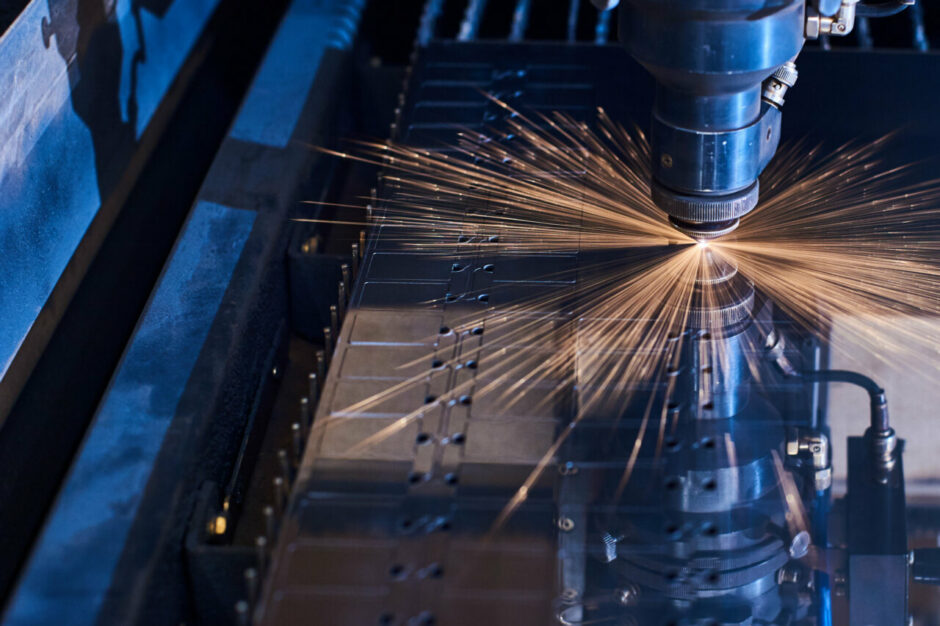

Laser Cutting and Welding

High dynamic characteristics enable precise, high-speed cutting and welding of large-scale parts.

Friction Stir Welding

Motion and force control ensure precise welding on freeform surfaces, where high dynamics and stiffness are crucial.

Composite Machining

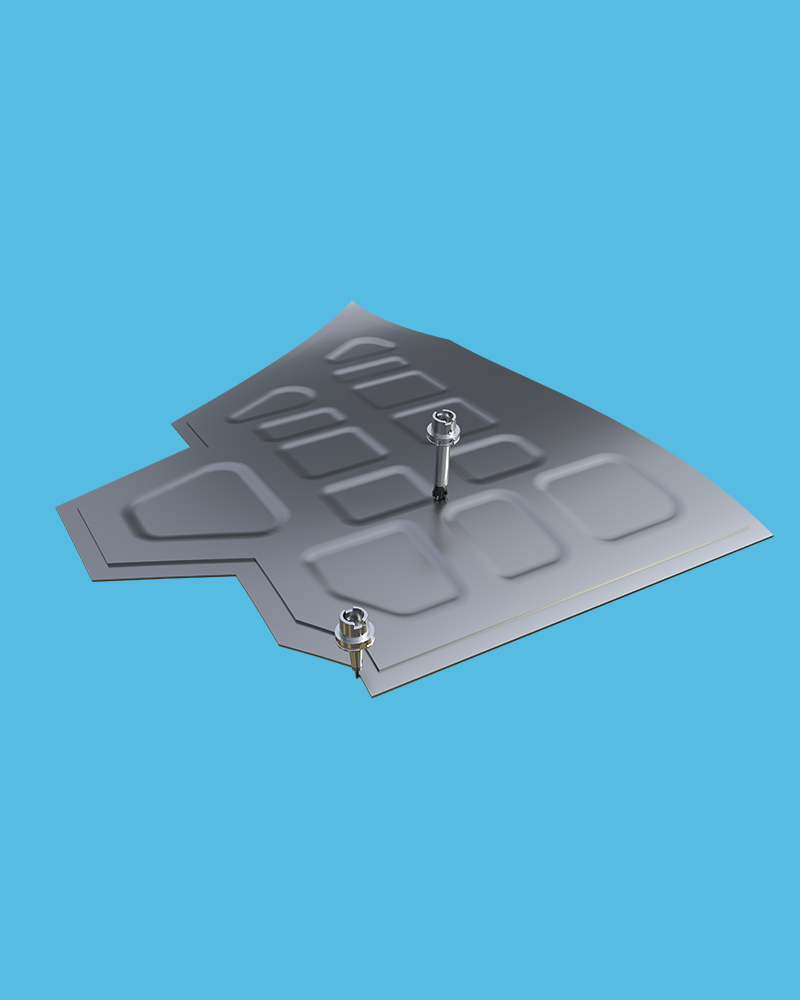

Gigacasting

With our PKM, we provide a powerful solution for the precise and rapid post-processing of Gigacasting parts.

The parallel kinematic module combines the advantages of machine tools and flexible robot machining. Large components, including castings, can be machined with unprecedented precision. Several modules combined with each other enable different machining steps such as laser cutting, milling and friction stir welding in one production line.

The modules can be flexibly adapted to the work area and offer higher accuracy and rigidity compared to conventional serial robots.

The PKM closes the gap between machine tools and conventional serial robots. It offers high flexibility and can be integrated into existing or new production lines. With a large working area and high speed, it offers versatile applications.

The PKM was developed in cooperation with our Swedish partner Cognibotics.

20x less moving mass

Up to 170 m/min

Up to 2.5 g

<= 5 μm

<= 40 μm

Width = 3m, Height = 2m, Length = No limit

Experience the future of robotics technology with the ELHA Parallel Kinematics Module. Contact us today to learn more about the applications and configurations that will take your manufacturing to the next level.

There is even more information for you here: