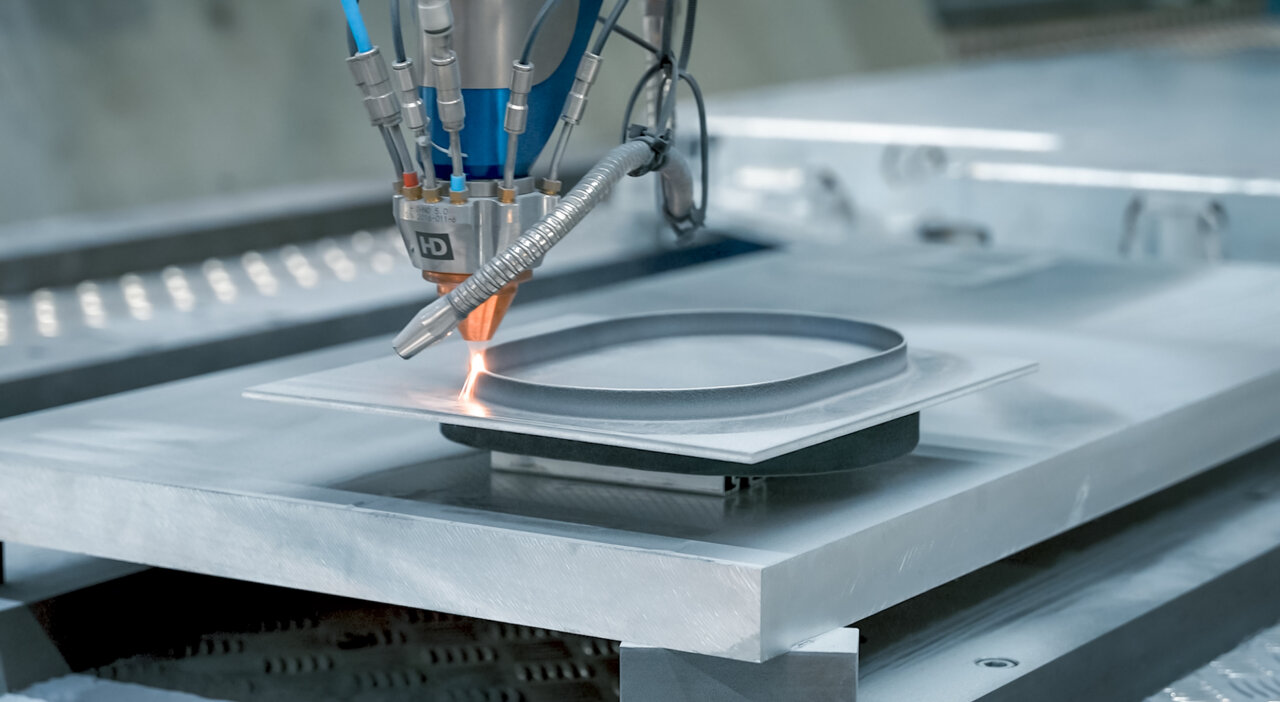

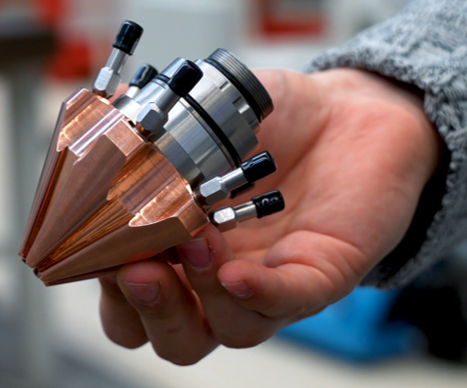

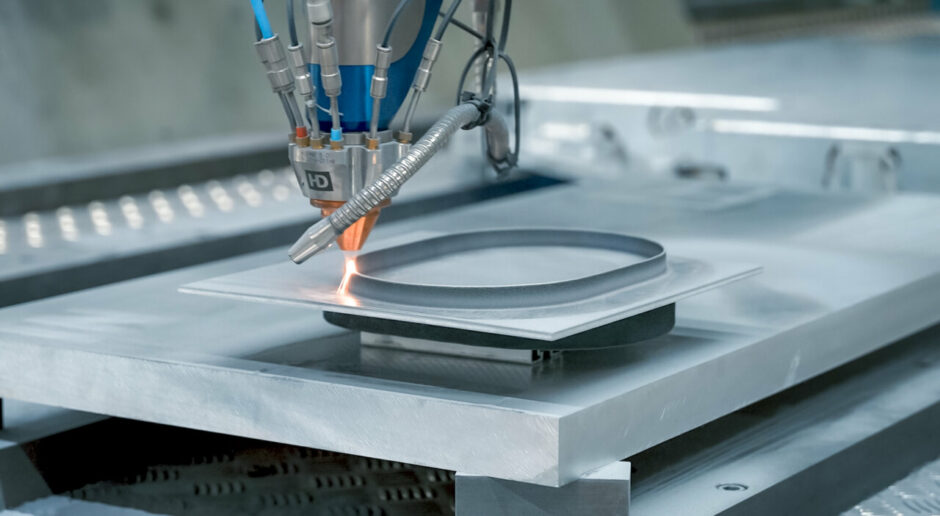

Dynamic Material Deposition (3DMD) combines powder-based laser deposition welding with Additive Manufacturing of metallic components. In this process, a laser melts the material which is then deposited onto a substrate. This method speeds up production, decreases energy consumption, and minimizes warping.

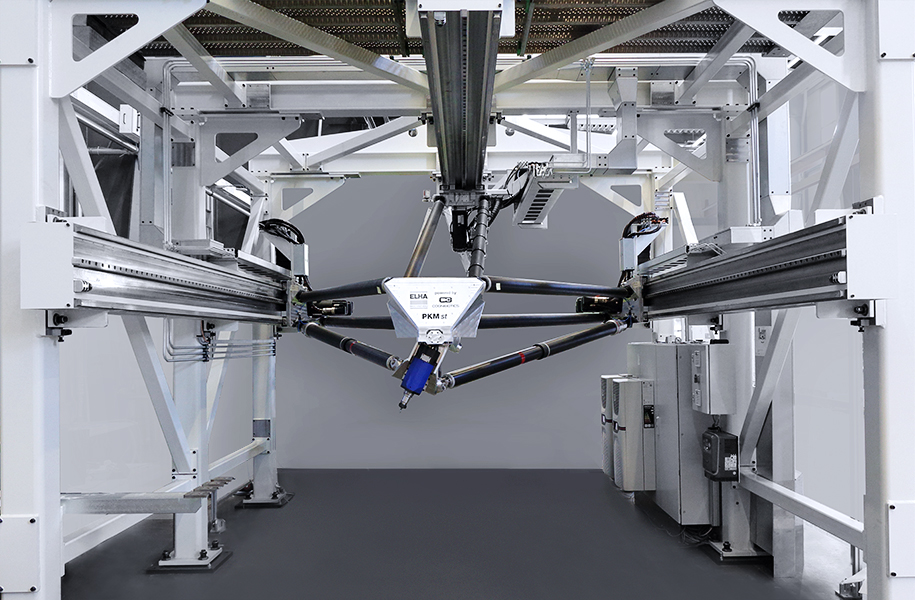

Additive Manufacturing has a notable limitation: while it produces small parts with high precision, large components often lack detail and quality. The hybrid SigmaTau equipped with a DED (Directed Energy Deposition) or a 3DMD process addresses this issue, enabling economical production of large components without sacrificing precision.

Originally, the 3DMD process was primarily used for coating components. However, its capability to process various alloys and metals through a nozzle-based powder supply makes it extremely versatile. Applications include:

The implementation of the 3DMD process demands machinery that can achieve both rapid operations and meticulous precision, requiring strong stiffness and dynamic capabilities. The SigmaTau robot’s design enables high surface rates of up to 1,000 cm²/min and build rates of up to 600 cm³/h. It is specifically engineered to maintain speed in all directions and reorientations to keep as close to net shape as possible, supporting efficient production.

Together with Cognibotics and technology partner Ponticon, ELHA-MASCHINENBAU has successfully integrated the dynamic material separation process (3DMD) into the PKM. This collaboration has resulted in a versatile system that is able to handle the production and machining of complicated components made from a variety of alloys and elementary metals.

In addition, a more compact version of the PKM was designed in this way, to fit inside a standard 40-foot container, providing a workspace measuring 1.2×1.2×2.5 meters. This design facilitates easy transportation and supports additive manufacturing and machining operations within a single setup. It offers the versatility to handle both production and repairs, whether in-house or on-site. Additionally, an advanced calibration system quickly restores precision after transportation, maintaining consistent accuracy in any environment.

In collaboration with Ponticon, we focussed on the so-called 3DMD process, which, in combination with the PKM, guarantees extremely fast and precise production rates. The workspace, which with the PKM is up to 4,000 x 3,000 x 2,000 mm and offers the possibility of 3- and 5-axis machining, opens up new dimensions for additive manufacturing.

Fast

The highly dynamic kinematics of the PKM machines enables surface rates up to 1,000 cm²/min and build rates up to 600 cm³/h.

Precise

Reproducible production of filigree 3D-structures with a minimum wall thickness of 500 μm and roughness of about 20 μm.

Flexible

Combination of diverse alloy systems and elementary metals with nozzle-based powder supply.

Find out more about the PKM:

Click here to return to the overview page

Contact us:

Do you have questions about the PKM?