From the early days of mass production for metal cutting workpieces until now there were a lot of improvements in production technology to maximize profitability. New work materials and optimized tool technology led to a dramatic reduction of cutting times over the years.

There was also a significant reduction of non-productive idle times in recent years due to improved machine tool technologies, but it didn´t keep pace at all with reduction of productive times. Especially for mass production parts which require a lot of different tools with short cutting times, such as for drilling or threading, this means a huge leak of total productivity.

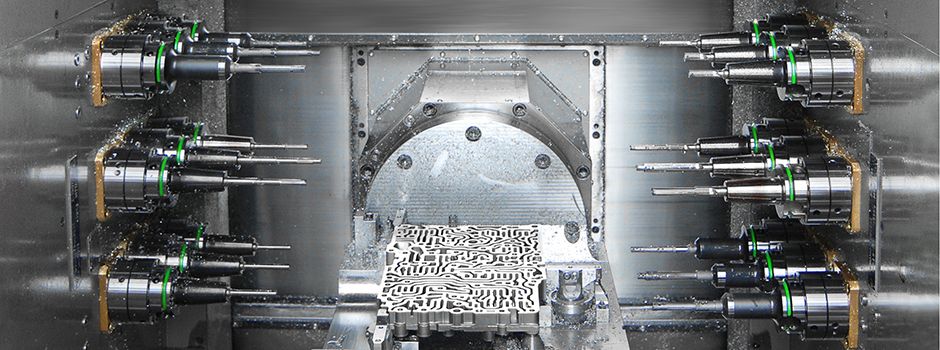

This was a good reason for ELHA to work hard on a solution. As a result ELHA developed and established a brilliant machining concept which has sustainably revolutionized the metal cutting industry, especially for mass production applications.