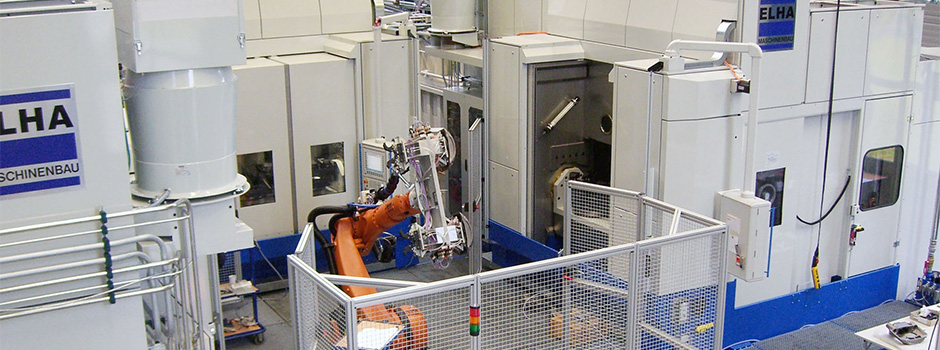

This machine was designed for the machining of HGV brake calipers with a clamping system. Various work piece varieties can be machined on the same clamping device since the clamping points are identically arranged for all work piece varieties.

For complex machining the machine was equipped with a swivel bridge (A-axis), which is driven by Ø 500 mm torque-motors on both sides. Two Ø 500 mm torque-motor driven swiveling tables (B-axis) are installed on the swivel bridge. All rotary axes are equipped with hydraulic clamping units.

The two work units can travel totally independent allowing adjustment options for tool lengths and tool diameters in all three axes. This machine is also equipped with a 80-slot pick-up tool magazine. This magazine is capable of holding a number of large drill- and milling heads.

| Technical Details | ||

|---|---|---|

| Traverse path | X-axes | 500 mm |

| Y-axes (tool change) | 500 (925) mm | |

| Z-axes | 500 mm | |

| Feed rates | max. speed | 40 m/min |

| max. acceleration | 4 m/sec² | |

| max. feed force | 10000 N | |

| Work unit | max. capacity S1 / S6 | 50 / 75 kW |

| max. torque S1 / S6 | 256 / 386 Nm | |

| max. speed | 7500 rpm | |

| spindle distance | 800 mm | |

| Swivel axes | diameter A-axes / number | ∅ 500 mm (1x) |

| diameter B-axes / number | ∅ 500 mm (2x) | |

| Tool magazine | tool slots | 80 |

| tool holder | HSK-A 100 | |

| tool changing rate | 8 sec | |

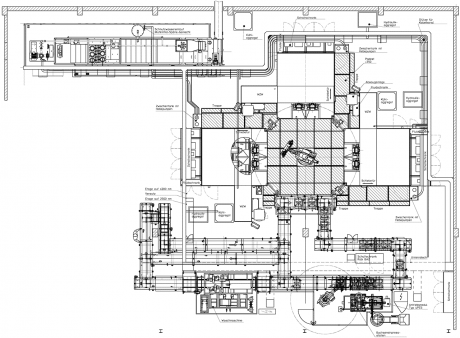

| Dimensions / Other | space assignment | 6.0 x 5.2 x 4.5 m |

| total weight | 34000 kg | |

| floor-to-floor time | 133 sec | |