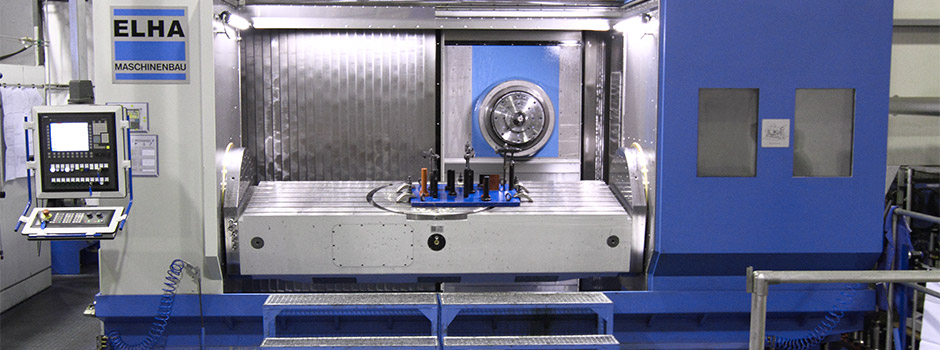

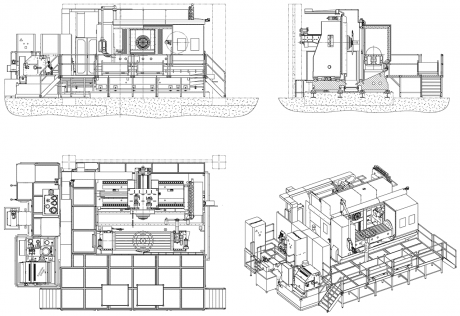

This new 5-axis special horizontal machining center stands for a whole new generation of ultra-robust and high-performance machines with outstanding features for the machining of most heavy-duty materials like titanium, Inconel and other materials and alloys primarily used in the aerospace sector.

This machine also uses the hydrostatic guided Z-axis-ram already known from our large Production Module series FM 4+X hd. The excellent vibration-absorbing and stabilizing features of this axis as well as the high- performance milling drive with a 37 kW strong HSK-A 125 in combination with the base machine made of composite-material result in record setting metal cutting capacities, precision and finish qualities! Thanks to the 3000 mm long and 1000 mm wide swing rotary table with an integrated rotary table of 1000 mm a wide work piece range of chassis parts up to large structural components can be machined, not only for the aerospace sector.

Machine description

| Technical Details | ||

|---|---|---|

| Traverse path | X-axis | 2500 mm |

| Y-axis | 1150 mm | |

| Z-axis | 1000 mm | |

| Feed rates | max. speed X / Y / Z | 30 / 30 / 48 m/min |

| max. acceleration X / Y / Z | 1.3 / 3 / 4 m/sec² | |

| max. feed force | 20000 N | |

| Main drive | max. capacity S1 | 37.7 kW |

| max. torque S1 (1 / 2) | 1425 / 285 Nm | |

| max. speed | 4000 rpm | |

| ram cross section | Ø450 mm | |

| Bridge / Round table | bridge size | 3000 x 1000 mm |

| bridge rotary table | 800 mm | |

| table diameter | 1000 mm | |

| Tool magazine | tool slots | 60 |

| tool holder | HSK-A 125 | |

| tool length / diameter | 500 / ∅250 mm | |

| Dimensions | space assignment | 11.8 x 7.9 x 4.8 m |

| total weight | 70000 kg | |