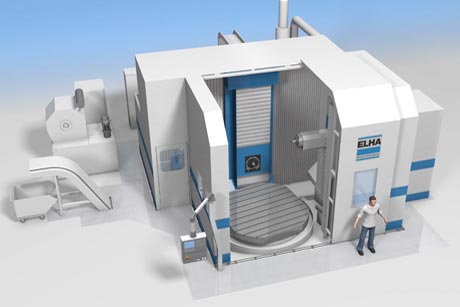

This machine was mainly designed for multi-spindle machining, horizontal drill- and milling of heavy cylinders. In order to allow the machining of other work pieces, the first unit was designed as dynamic box-in-box unit. This box-in-box unit features an increasing X-traverse path and a higher-capacity work spindle.

The three-part machine frame of the box-in-box unit and the two-part machine base were made of a vibration-reducing composite-material construction. The 2500 mm large CNC-rotary table was designed for extra heavy work pieces with a weight up to max. 45 tons. With this rotary table any angle with an accuracy of ± 3 angular seconds can be positioned.

The use of manually adjustable, automatic exchangeable two-spindle drill heads in both units allows a considerable reduction of machining time. Two automatic tool magazines are additionally able to hold further drill- and milling tools.

| Technical Details | ||

|---|---|---|

| Traverse path | X1 / X2-axis | 2500 / 200 mm |

| Y1 / Y2-axis | 1800 mm | |

| Z1 / Z2-axis | 1000 mm | |

| Feed rates | max. speed | 30 m/min |

| Main drive 1 | max. capacity S1 / S6 | 28 / 42 kW |

| max. torque | 534 / 2136 Nm | |

| max. speed | 3000 rpm | |

| Main drive 2 | max. capacity S1 / S6 | 33 / 45 kW |

| max. torque S1 / S6 | 157 / 215 Nm | |

| max. speed | 10000 rpm | |

| Rotary table | diameter | 2500 mm |

| max. speed | 6 rpm | |

| Tool magazine | tool slots | 3 + Head |

| tool holder | HSK-A 100 | |

| Dimensions | space assignment | 11.7 x 9.3 x 6.0 m |

| total weight | 166000 kg | |