ELHA offers a great variety of peripheral equipment to optimize the FM SMART for the specific machining tasks.

|

|

|

| SMART | Series 1 | Series 2 |

|---|---|---|

| COOLANT / CHIP DIPOSAL | ||

| Coolant system, water based | ○ | ○ |

| Coolant system, oil based | ○ | ○ |

| High pressure pump size I or II | ○ | ○ |

| Duplex filter | ○ | ○ |

| Chip conveyor | ○ | ○ |

| Coolant gun | ○ | ○ |

| MECHANICS | ||

| Exhausting unit | ○ | ○ |

| Fixture change support unit | ○ | ○ |

| Preparation for additional unit | X | ○ |

| Cone cleaning | ○ | ○ |

| High dynamic package | X | ○ |

| AUTOMATION | ||

| Level I | ⬤ | ⬤ |

| Level II (with pallet conveyor) | ○ | ○ |

| ELECTRIC / CNC | ||

| Remote diagnosis | ○ | ○ |

| Load monitoring | ○ | ○ |

| Shop Mill | ○ | ○ |

| Virtual machine | ○ | ○ |

| Measuring probe | ○ | ○ |

| PROCESS ENGINEERING | ||

| Geometrical acceptance | ○ | ○ |

| Tool scheme | ○ | ○ |

| NC-programming | ○ | ○ |

| Work fixture design | ○ | ○ |

| SERVICES | ||

| Simulation | ○ | ○ |

| Cycle time calculation | ○ | ○ |

| Transport | ○ | ○ |

| Reassembly and commissioning | ○ | ○ |

| Production support | ○ | ○ |

| TRAINING | ||

| Mechanics / Hydraulics | ○ | ○ |

| Electrics / Electronics | ○ | ○ |

| Operation / Programming | ○ | ○ |

| Making of work fixture | ○ | ○ |

| ⬤ = standard, ○ = option, X = not available | ||

The ELHA virtual machine is a productive simulation tool, which connects all relevant machine parameters with the process data from customers CAD/CAM system. Therefore it is possible to generate very precise process studies and simulations incl. 3D collision control. This solution helps to evaluate and improve machining processes and to reduce time for machine setup.

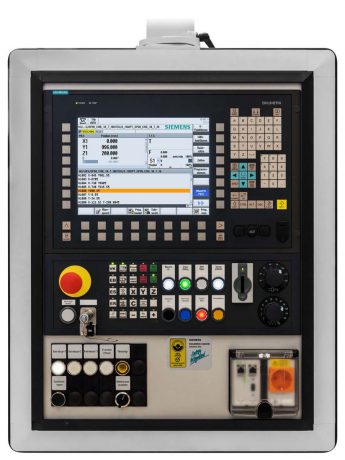

The standard CNC for highly productive machining solutions.