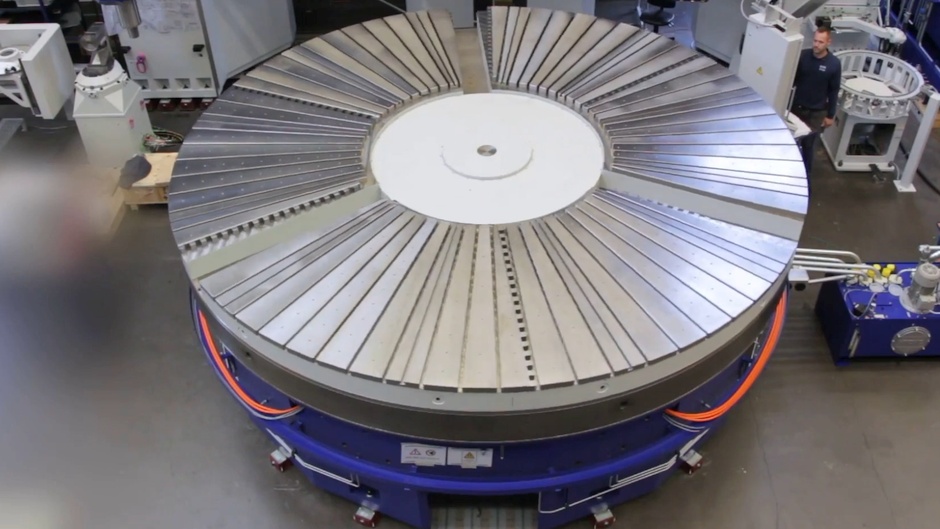

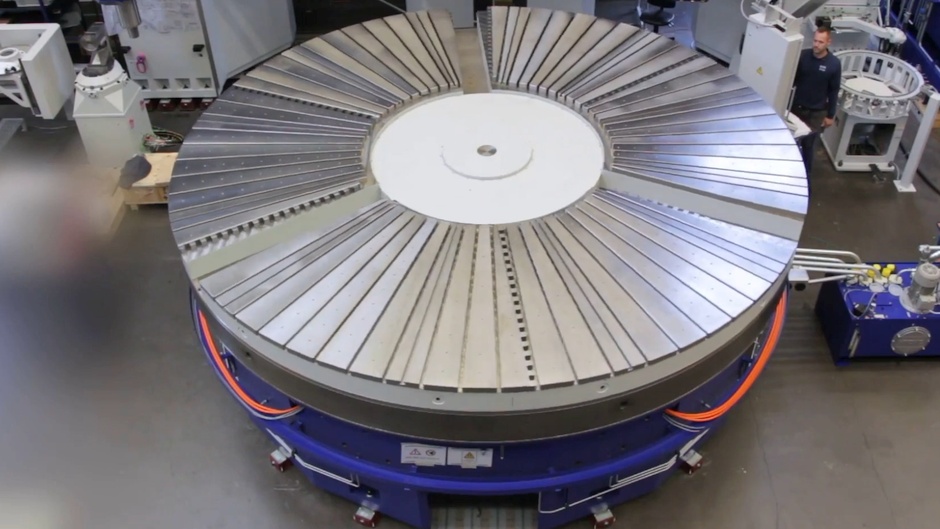

The table drive is the heart of the vertical multi-tasking machine and its performance in machining quality

and dynamics directly influences the ultimate workpiece quality and economy of the machine. ELHA sets

new standard with the patented SDD (Segment Direct Drive) table direct drive using the following features:

- Extremely high control stiffness and positional accuracy of approx. ± 1“

- High acceleration and positioning dynamics (VTM 402: 0 – 80 rpm in 6 sec with approx. 40 t moving mass)

- Optimal machining quality without any influence of engaging gear frequencies

- Broad power-, torque- and rpm spectrum with proven standard components based on linear drive technology

- Optimal run-out because of elimination of radial drive forces and use of a radial hydrostatic bearing

- Very low noise emission

- No wear of drive components with minimal maintenance, continued use of the rotary table after failure of individual motor segments

- Excellent thermo-symmetrical temperature control of the entire rotary table foundation with minimal deformation

ELHA SDD Table as a Retrofit-Set

Because of the modular character of the VTM the ELHA SDD rotary table can be used as a stand-alone unit,

for example as part of a retrofit or maintenance of existing machines. This presents the possibility to

use the extraordinary precision, dynamics and technology of this rotary table design in your existing machine

park to achieve significant quality and productivity improvements.

Hydrostatic guides for all linear and rotary axes

Rotary table radial bearing

Rotary table axial bearing